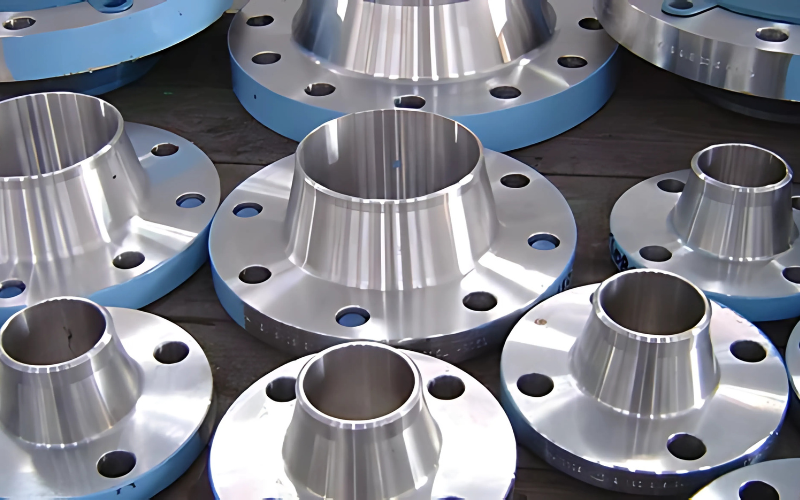

Duplex Steel Flanges

Enquire Now

Duplex Steel Flanges – High-Performance Solutions by Pearl Steel

At Pearl Steel, we specialize in offering a wide range of duplex steel flanges designed to meet the diverse needs of global industries. Known for their exceptional corrosion resistance, superior mechanical strength, and long-lasting performance, these flanges are manufactured using duplex stainless steel, a material composed of nearly equal proportions of austenitic and ferritic stainless steel. This unique combination delivers higher strength and resistance to stress corrosion cracking compared to conventional stainless grades.

Specifications and Industrial Applications

Our duplex stainless steel fittings and flanges are widely utilized across sectors such as oil and gas, petrochemical, marine engineering, chemical processing, and offshore industries. These flanges are built to endure extreme operating conditions, including high pressure, corrosive media, and elevated temperatures. Whether you’re connecting pipes, valves, pumps, or other critical equipment, Pearl Steel’s duplex steel flanges ensure safe, leak-free operations.

Types of Duplex Steel Flanges We Offer

We supply a comprehensive variety of duplex steel flange types to suit different engineering and piping requirements:

- Lap Joint Pipe Flanges: Ideal for systems requiring frequent disassembly for inspection or cleaning, especially in corrosive environments.

- Duplex Threaded Forged Flanges: Feature internal threads for easy installation without welding – perfect for low-pressure, non-cyclic operations.

- Weld Neck Forged Flanges: With a tapered hub for butt welding, these flanges ensure high structural strength and seamless flow.

- Slip-On Flanges Exporter: Our slip-on flanges are easy to align and install, making them ideal for low-pressure, non-critical connections.

- Socket Welding Flanges Stockist: Designed for small-diameter, high-pressure piping. The pipe is inserted into a recessed area of the flange and then welded.

- Duplex Steel Long Weld Neck Flanges: These flanges are ideal for high-pressure applications where added reinforcement is required.

- Duplex Steel Socket Weld Flanges: Offer enhanced fatigue strength and are perfect for high-pressure systems involving small pipe sizes.

We also stock premium Duplex UNS S32205 flanges and Duplex UNS S31803 flanges, engineered to meet international standards and offer excellent strength, durability, and resistance in chloride-rich environments.

Advantages of Choosing Duplex Steel Flanges from Pearl Steel

- Corrosion Resistance: Excellent resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking.

- High Strength: With higher yield and tensile strength than standard austenitic steels, these flanges offer improved reliability.

- Cost Efficiency: Reduced wall thickness and longer life mean lower lifecycle costs.

- Versatility: Suitable for both low and high-pressure, high-temperature, and corrosive environments.

- Resistance to SCC: Our duplex stainless steel flanges are highly resistant to stress corrosion cracking, ensuring durability in aggressive media.

Manufacturing Process of Duplex Steel Flanges

- Raw Material Inspection: Quality control begins with a thorough inspection of raw materials for compliance with test certificates and visual standards.

- Material Cutting: Precise cutting from duplex stainless plates or billets, followed by rolling or forming into required flange shapes.

- Forging: Our duplex forged flanges, including weld neck forged flanges and duplex threaded forged flanges, are created through controlled forging methods for superior grain structure and strength.

- Heat Treatment: This step enhances the mechanical properties by optimizing the microstructure and reducing internal stresses.

- Final Inspection: Every flange undergoes dimensional checks, surface evaluation, and testing for mechanical and chemical integrity.

Chemical Composition

Typical composition of duplex stainless steel flanges includes:

- Chromium (Cr): Enhances corrosion resistance.

- Nickel (Ni): Adds toughness and improves weldability.

- Molybdenum (Mo): Boosts resistance to pitting and crevice corrosion.

- Nitrogen (N): Strengthens the steel and improves pitting resistance.

- Iron (Fe): Base element ensuring overall structural integrity.

Mechanical Properties

- Tensile Strength: 620 – 900 MPa

- Yield Strength: 450 – 700 MPa

- Elongation: 25% to 30%

- Hardness: 20 – 35 HRC

These mechanical properties make duplex steel flanges ideal for high-demand engineering environments requiring durability and performance.

Why Choose Pearl Steel?

Pearl Steel stands out as a trusted Supplier, exporter, and stockist of premium-grade duplex steel flanges, including Duplex UNS S32205 flanges, UNS S31803 flanges, and a wide range of duplex stainless steel fittings and flanges. Our dedication to quality assurance, timely delivery, and competitive pricing makes us the preferred partner for industries around the world.

Whether you’re looking for lap joint pipe flanges, slip-on flanges, socket welding flanges, or weld neck forged flanges, Pearl Steel guarantees engineering excellence and unmatched customer support.